关于火电厂的脱硫工艺,你知道几种? - 知乎,炉内喷钙加尾部烟气增湿活化脱硫工艺是在炉内喷钙脱硫工艺的基础上在锅炉尾部增设了增湿段,以提高脱硫效率。 该工艺多以石灰石粉为吸收剂,石灰石粉由气力喷入炉

石灰石-石膏湿法烟气脱硫工艺技术 - 知乎,当采用石灰作为吸收剂时,石灰粉经消化处理后加 水, 该技术采 用单循环喷雾空塔结构,具有技术成熟、应用范围广、脱硫效率, 烟气中的杂质,包括部分的s02、灰尘、hci

什么是炉内喷钙(石灰石粉)脱硫技术? - 搜狐,2016年7月12日 炉内喷钙(石灰石)烟气脱硫系统主要适用于燃煤炉发电厂锅炉脱硫用,该系统主要任务是完成物料输送、计量、送粉量调节、炉内喷射,从而使石灰石粉在炉内锻烧分解,利用生成的CaO与炉内烟气中

煤粉工业锅炉添加生石灰燃烧的脱硫效率实验研究_范,,摘 要:针对煤粉工业锅炉炉内喷生石灰的脱硫技术进行研究,并对不同钙硫比、不同炉膛温度的 脱硫效率进行比较。 结果表明:炉膛温度和钙硫比是影响炉内脱硫效率的2个主要

浅谈提高石灰石脱硫效率的方法 - 北极星环保网,2017年2月22日 文章通过探讨化学物质、运行条件和系统设备对脱硫石膏品质的影响,深入分析了提升石灰石脱硫效率的方法,为改善和稳定脱硫石膏品质提供参考。

干法脱硫——炉内喷钙工艺 华林环境工程(江苏,,干法脱硫—炉内喷钙工艺技术特点. 1、该系统具有配置简洁、能耗低、无污染、自动化程度高、操作简单、占用空间小、投资省、脱硫效率较高;. 2、适用于燃中低硫煤,也可用于燃高硫煤。. 能以合理的钙硫比,得到较高

炉内脱硫原理 - 百度文库,理论上讲脱硫剂越小炉内脱硫效果越好因为减少石灰石粒径能增加其表面积从而提高反应面积。 但脱硫剂并非越小越好如果脱硫剂太小就会有很大部分随着烟气逃逸增加尾部烟道的

CN111485088A - 一种解决铌微合金化hrb400e, - Google PatentsCN111485088A CN202010174523.3A CN202010174523A CN111485088A CN 111485088 A CN111485088 A CN 111485088A CN 202010174523 A CN202010174523 A CN 202010174523A CN 111485088 A CN111485088 A CN 111485088A Authority CN China Prior art keywords temperature water tank phi steel bars discharged Prior art date 2020

CN213699451U - 一种半干法脱硫设备的多介质雾化装置,CN213699451U CN202022116845.0U CN202022116845U CN213699451U CN 213699451 U CN213699451 U CN 213699451U CN 202022116845 U CN202022116845 U CN 202022116845U CN 213699451 U CN213699451 U CN 213699451U Authority CN China Prior art keywords supply mechanism detection unit pressure detection pipeline semi

CN106268214A - 一种脱硫剂的制备方法及其脱硫剂 - Google,CN106268214A CN201610782058.5A CN201610782058A CN106268214A CN 106268214 A CN106268214 A CN 106268214A CN 201610782058 A CN201610782058 A CN 201610782058A CN 106268214 A CN106268214 A CN 106268214A Authority CN China Prior art keywords preparation desulfurizing agent butylene succinate poly butylene

CN102020369B - 一种脱硫废水处理工艺 - Google Patents,CN102020369B CN2010105482110A CN201010548211A CN102020369B CN 102020369 B CN102020369 B CN 102020369B CN 2010105482110 A CN2010105482110 A CN 2010105482110A CN,

WO2017185564A1 - 自适应沸腾式泡沫脱硫除尘装置 - Google,,WO2017185564A1 PCT/CN2016/095407 CN2016095407W WO2017185564A1 WO 2017185564 A1 WO2017185564 A1 WO 2017185564A1 CN 2016095407 W CN2016095407 W CN 2016095407W WO 2017185564 A1 WO2017185564 A1 WO 2017185564A1 Authority WO WIPO (PCT) Prior art keywords desulfurization adaptive

CN109351173B, - Google Patents,CN109351173B CN201811503940.7A CN201811503940A CN109351173B CN 109351173 B CN109351173 B CN 109351173B CN 201811503940 A CN201811503940 A CN 201811503940A CN 109351173 B CN109351173 B CN 109351173B Authority CN China Prior art keywords circulating ash desulfurization stirring circulating ash Prior art date

CN209254482U - 一种节能型脱硫提效装置 - Google Patents,CN209254482U CN201821901870.6U CN201821901870U CN209254482U CN 209254482 U CN209254482 U CN 209254482U CN 201821901870 U CN201821901870 U CN 201821901870U CN 209254482 U CN209254482 U CN 209254482U Authority CN China Prior art keywords turbulent flow energy effect device flow module stud Prior art date

CN211864516U - 一种水泥厂脱硫脱硝用废气处理装置,,CN211864516U CN201922432446.2U CN201922432446U CN211864516U CN 211864516 U CN211864516 U CN 211864516U CN 201922432446 U CN201922432446 U CN 201922432446U CN 211864516 U CN211864516 U CN 211864516U Authority CN China Prior art keywords pipe spraying branch pipe spray hole Prior art date 2019-12-30 Legal

CN102266718A, - Google Patents,CN102266718A CN2011100207554A CN201110020755A CN102266718A CN 102266718 A CN102266718 A CN 102266718A CN 2011100207554 A CN2011100207554 A CN 2011100207554A CN 201110020755 A CN201110020755 A CN 201110020755A CN 102266718 A CN102266718 A CN 102266718A Authority CN China Prior art keywords

CN102527196B, - Google Patents,CN102527196B CN2012100310244A CN201210031024A CN102527196B CN 102527196 B CN102527196 B CN 102527196B CN 2012100310244 A CN2012100310244 A CN 2012100310244A CN 201210031024 A CN201210031024 A CN 201210031024A CN 102527196 B CN102527196 B CN 102527196B Authority CN China Prior art keywords

CN1012589B - 双流化床式锅炉 - Google PatentsCN1012589B CN88101563.6A CN88101563A CN1012589B CN 1012589 B CN1012589 B CN 1012589B CN 88101563 A CN88101563 A CN 88101563A CN 1012589 B CN1012589 B CN 1012589B Authority CN China Prior art keywords burning zone boiler fluid bed section bed Prior art date 1987-03-23 Legal status (The legal status is an assumption and is not

CN210699437U - 一种半干法脱硫设备 - Google PatentsCN210699437U CN201921237207.5U CN201921237207U CN210699437U CN 210699437 U CN210699437 U CN 210699437U CN 201921237207 U CN201921237207 U CN 201921237207U CN 210699437 U CN210699437 U CN 210699437U Authority CN China Prior art keywords communicated semi ash bag dry desulfurization Prior art date 2019-08

CN212818976U - 油页岩半焦制备铁红颜料的烟气净化装置,CN212818976U CN202021648506.0U CN202021648506U CN212818976U CN 212818976 U CN212818976 U CN 212818976U CN 202021648506 U CN202021648506 U CN 202021648506U CN 212818976 U CN212818976 U CN 212818976U Authority CN China Prior art keywords flue gas smoke desulfurizer pigment iron oxide Prior art date 2020-08

CN106268215A - 一种脱硫剂的制作方法及制得的脱硫剂,,CN106268215A CN201610788650.6A CN201610788650A CN106268215A CN 106268215 A CN106268215 A CN 106268215A CN 201610788650 A CN201610788650 A CN 201610788650A CN 106268215 A CN106268215 A CN 106268215A Authority CN China Prior art keywords desulfurizing agent manufacture method butylene succinate poly

CN110465160A - 一种半干法脱硫设备 - Google Patents,CN110465160A CN201910706850.6A CN201910706850A CN110465160A CN 110465160 A CN110465160 A CN 110465160A CN 201910706850 A CN201910706850 A CN 201910706850A CN 110465160 A CN110465160 A CN 110465160A Authority CN China Prior art keywords semi former flue bag filter dry desulphurization flue Prior art date 2019

CN107694320A - 侧进式高效脱硫喷淋装置 - Google Patents,CN107694320A CN201710914497.1A CN201710914497A CN107694320A CN 107694320 A CN107694320 A CN 107694320A CN 201710914497 A CN201710914497 A CN 201710914497A CN 107694320 A CN107694320 A CN 107694320A Authority CN China Prior art keywords spray equipment desulfurizing tower spraying layer type high feeding

CN110732235A - 一种基于循环半干法烟气脱硫设备 - Google,,CN110732235A CN201911027976.7A CN201911027976A CN110732235A CN 110732235 A CN110732235 A CN 110732235A CN 201911027976 A CN201911027976 A CN 201911027976A CN 110732235 A CN110732235 A CN 110732235A Authority CN China Prior art keywords heat exchange flue gas gas desulfurization heat exchange

CN102527196A, - Google Patents,CN102527196A CN2012100310244A CN201210031024A CN102527196A CN 102527196 A CN102527196 A CN 102527196A CN 2012100310244 A CN2012100310244 A CN 2012100310244A CN 201210031024 A CN201210031024 A CN 201210031024A CN 102527196 A CN102527196 A CN 102527196A Authority CN China Prior art keywords

,

,

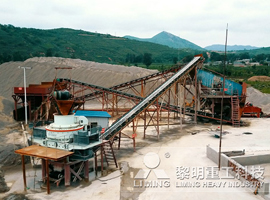

石灰石固废处理项目

西藏日喀则页岩破碎生产线

湖南衡阳河卵石制砂生产线

泰国玄武岩制砂生产线

版权所有:黎明重工 备案号: 豫ICP备10200540号-22