白炭黑知识篇:气相法白炭黑和沉淀法白炭黑的区别,,1.白炭黑生产方法. 制备白炭黑的传统方法是利用硅酸钠、四氯化硅、正硅酸乙酯做硅源,除硅酸钠以外,其它成本都较高。新方法采用廉价的非金属矿作为硅源,大大降低了白炭

中国炭黑产业现状概述 - 知乎,1. 什么是炭黑? 碳黑,又名炭黑,是一种无定形碳。 轻、松而极细的黑色粉末,形象简单的理解一下可以想象成锅底灰。 它是含碳物质 (煤、天然气、重油、燃料油等)在空气不足的条件下经不完全燃烧或受热分解而得的产物

白炭黑的制备技术与应用技术进展(图文) - 硅微粉官网,,一是以水玻璃为原料的沉淀法,二是以四氯化硅为原料的气相法。 气相法白炭黑的生产工艺主要为化学气相沉积 (CVD)法,该工艺又称热解法、干法或燃烧法。 其原料一般为四氯化

山和机械白炭黑专用粉碎机简介 - 知乎,2023年6月26日 山和白炭黑专用粉碎机适用于白炭黑等比重轻的物料粉碎,广泛应用于橡胶制品、纺织、造纸、农药、食品添加剂等领域。 该设备可以粉碎各种硬度和脆性的物

高分散性白炭黑的生产方法及设备 - 粉体网,高分散性白炭黑的生产方法及设备,粉碎程度超细粉碎,单位能耗0-10,产量300-40000,装机功率(kw)4-110,成品细度0-0.2,入料粒度(mm)0-100,工作原理辊压碾磨,上海依肯机械设备

生产白炭黑需要什么机械设备?什么原材料? - 百度知道,有两种:气相法白炭黑和液相法白炭黑。 都需要大型设备,配套工序多,工艺复杂,不是小作坊可以做的。 你是要从事这个行业么?本人不才与几家白炭黑厂家有关系,或许可以

CN202460692U - 能向碾米机均匀供料的大米加工配套设备,,CN202460692U CN2012200915685U CN201220091568U CN202460692U CN 202460692 U CN202460692 U CN 202460692U CN 2012200915685 U CN2012200915685 U CN 2012200915685U CN 201220091568 U CN201220091568 U CN 201220091568U CN 202460692 U CN202460692 U CN 202460692U Authority CN China Prior art keywords

KR100464691B1 - 침강실리카,이의제조방법및이를포함,KR100464691B1 KR10-1998-0054310A KR19980054310A KR100464691B1 KR 100464691 B1 KR100464691 B1 KR 100464691B1 KR 19980054310 A KR19980054310 A KR 19980054310A KR 100464691 B1 KR100464691 B1 KR 100464691B1 Authority KR South Korea Prior art keywords din precipitated silica equation index size distribution

KR100464691B1 - 침강실리카,이의제조방법및이를포함,KR100464691B1 KR10-1998-0054310A KR19980054310A KR100464691B1 KR 100464691 B1 KR100464691 B1 KR 100464691B1 KR 19980054310 A KR19980054310 A KR 19980054310A KR 100464691 B1 KR100464691 B1 KR 100464691B1 Authority KR South Korea Prior art keywords din precipitated silica equation index size distribution

CN104707685A - 涂料分类别粉碎机 - Google PatentsCN104707685A CN201310683428.6A CN201310683428A CN104707685A CN 104707685 A CN104707685 A CN 104707685A CN 201310683428 A CN201310683428 A CN 201310683428A CN 104707685 A CN104707685 A CN 104707685A Authority CN China Prior art keywords powder classification pulverizer crushing pulverizing Prior art date

CN207413582U, - Google Patents,CN207413582U CN201720999111.7U CN201720999111U CN207413582U CN 207413582 U CN207413582 U CN 207413582U CN 201720999111 U CN201720999111 U CN 201720999111U CN 207413582 U CN207413582 U CN 207413582U Authority CN China Prior art keywords raw material pulverizer pipeline level cyclone Prior art date 2017-08

CN205042604U - 一种超细溴化环氧树脂粉末的生产设备,,CN205042604U CN201520742551.5U CN201520742551U CN205042604U CN 205042604 U CN205042604 U CN 205042604U CN 201520742551 U CN201520742551 U CN 201520742551U CN 205042604 U CN205042604 U CN 205042604U Authority CN China Prior art keywords feed bin stainless steel automatic packaging packaging machine

CN201472919U - 组合式稳流称重仓 - Google Patents,CN201472919U CN2009201874943U CN200920187494U CN201472919U CN 201472919 U CN201472919 U CN 201472919U CN 2009201874943 U CN2009201874943 U CN 2009201874943U CN 200920187494 U CN200920187494 U CN 200920187494U CN 201472919 U CN201472919 U CN 201472919U Authority CN China Prior art keywords

CN104845411B - 超细重质碳酸钙粉体生产方法 - Google Patents,CN104845411B CN201510290132.7A CN201510290132A CN104845411B CN 104845411 B CN104845411 B CN 104845411B CN 201510290132 A CN201510290132 A CN 201510290132A CN 104845411 B CN104845411 B CN 104845411B Authority CN China Prior art keywords powder calcium carbonate mesh wet granularity Prior art date 2015

KR100464691B1 - 침강실리카,이의제조방법및이를포함,,KR100464691B1 KR10-1998-0054310A KR19980054310A KR100464691B1 KR 100464691 B1 KR100464691 B1 KR 100464691B1 KR 19980054310 A KR19980054310 A KR 19980054310A KR 100464691 B1 KR100464691 B1 KR 100464691B1 Authority KR South Korea Prior art keywords din precipitated silica equation index size distribution

CN104211312A - 一种水泥外循环立磨半终粉磨系统 - Google,,2022年4月1日 CN104211312A CN201410481631.XA CN201410481631A CN104211312A CN 104211312 A CN104211312 A CN 104211312A CN 201410481631 A CN201410481631 A CN 201410481631A CN 104211312 A CN104211312 A CN 104211312A Authority CN China Prior art keywords vertical mill separating machine cement powder separating

CN102347479A, - Google Patents,CN102347479A CN2010102461767A CN201010246176A CN102347479A CN 102347479 A CN102347479 A CN 102347479A CN 2010102461767 A CN2010102461767 A CN 2010102461767A CN 201010246176 A CN201010246176 A CN 201010246176A CN 102347479 A CN102347479 A CN 102347479A Authority CN China Prior art keywords

CN202460582U - 快速除尘的干法辊压机 - Google PatentsCN202460582U CN2012200034663U CN201220003466U CN202460582U CN 202460582 U CN202460582 U CN 202460582U CN 2012200034663 U CN2012200034663 U CN 2012200034663U CN 201220003466 U CN201220003466 U CN 201220003466U CN 202460582 U CN202460582 U CN 202460582U Authority CN China Prior art keywords

JP3787446B2 - 沈降珪酸、被覆された状態での該化合物の,JP3787446B2 JP35012798A JP35012798A JP3787446B2 JP 3787446 B2 JP3787446 B2 JP 3787446B2 JP 35012798 A JP35012798 A JP 35012798A JP 35012798 A JP35012798 A JP 35012798A JP 3787446 B2 JP3787446 B2 JP 3787446B2 Authority JP Japan Prior art keywords din silicic acid precipitated silicic particle size polyethylene wax Prior art date

MX2008001809A - Metodo para procesar polvo de nefelina MX2008001809A - Metodo para procesar polvo de nefelina sienita, para producir un producto con tamaño de grano ultra fino. - Google Patents

CN204411988U - 一种生物质燃料生产用送料吸尘回收装置,,CN204411988U CN201420800822.3U CN201420800822U CN204411988U CN 204411988 U CN204411988 U CN 204411988U CN 201420800822 U CN201420800822 U CN 201420800822U CN 204411988 U CN204411988 U CN 204411988U Authority CN China Prior art keywords dust dust suction shield frame biomass fuel Prior art date 2014-12-17

CN105709661B - 一种用于氧化锌循环造粒系统 - Google Patents,CN105709661B CN201610154649.8A CN201610154649A CN105709661B CN 105709661 B CN105709661 B CN 105709661B CN 201610154649 A CN201610154649 A CN 201610154649A CN 105709661 B CN105709661 B CN 105709661B Authority CN China Prior art keywords machine lifting device feeder tablet press crushed Prior art date 2016

CN204816805U - 一种纳米陶瓷母粒的制备系统 - Google Patents,CN204816805U CN201520557478.4U CN201520557478U CN204816805U CN 204816805 U CN204816805 U CN 204816805U CN 201520557478 U CN201520557478 U CN 201520557478U CN 204816805 U CN204816805 U CN 204816805U Authority CN China Prior art keywords nano inverted ventilation machine ball mill level grinder Prior art date

CN203791027U - 节能组合型磨粉机 - Google Patents,CN203791027U CN201420201479.0U CN201420201479U CN203791027U CN 203791027 U CN203791027 U CN 203791027U CN 201420201479 U CN201420201479 U CN 201420201479U CN 203791027 U CN203791027 U CN 203791027U Authority CN China Prior art keywords pulverizing flour mill breaking energy saving type Prior art date 2014

CN204211709U - 一种粉煤制备及输送系统 - Google Patents,CN204211709U CN201420653576.3U CN201420653576U CN204211709U CN 204211709 U CN204211709 U CN 204211709U CN 201420653576 U CN201420653576 U CN 201420653576U CN 204211709 U CN204211709 U CN 204211709U Authority CN China Prior art keywords gas coal entrance coal pulverizer fine coal Prior art date 2014-11-04

,

,

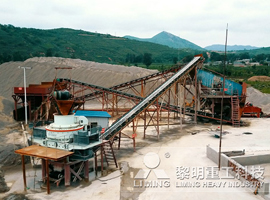

石灰石固废处理项目

西藏日喀则页岩破碎生产线

湖南衡阳河卵石制砂生产线

泰国玄武岩制砂生产线

版权所有:黎明重工 备案号: 豫ICP备10200540号-22